Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during HV floor under wire removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

|

*: When performing learning using the Techstream.

Click here | |||

| Auxiliary battery terminal is disconnected/reconnected | Perform steering sensor zero point calibration | Lane Control System | |

| Pre-collision System | |||

| Parking Support Brake System* | |||

| Lighting System | |||

| Memorize steering angle neutral point | Parking assist monitor system | | |

| Panoramic view monitor system | | ||

| Initialize power trunk lid system | Power Trunk Lid System | | |

| Inspection After Repair |

| |

CAUTION:

-

Orange wire harnesses and connectors indicate high-voltage circuits. To prevent electric shock, always follow the procedure described in the repair manual.

.png)

Click here

.gif)

-

To prevent electric shock, wear insulated gloves when working on wire harnesses and components of the high voltage system.

.png)

-

To prevent burns, do not touch the engine, exhaust manifold or other high temperature components while the engine is hot.

.png)

-

To prevent burns, do not touch the engine, exhaust pipe or other high temperature components while the engine is hot.

.png)

NOTICE:

- After the power switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the power switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) auxiliary battery terminal. (for Audio and Visual System)

- After the power switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the power switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) auxiliary battery terminal. (for Navigation System)

PROCEDURE

1. PRECAUTION

Click here .gif)

2. REMOVE SERVICE PLUG GRIP

Click here .gif)

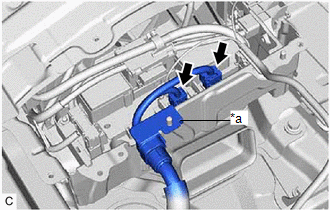

3. DISCONNECT ENGINE ROOM MAIN WIRE

CAUTION:

Be sure to wear insulated gloves.

NOTICE:

Do not allow any foreign matter or water to enter the inverter with converter assembly.

| (a) Move the lock lever while pushing the lock on the connector, and disconnect the inverter with converter assembly connector. NOTICE:

|

|

4. REMOVE CONNECTOR COVER ASSEMBLY

Click here .gif)

5. CHECK TERMINAL VOLTAGE

Click here .gif)

6. TEMPORARILY INSTALL CONNECTOR COVER ASSEMBLY

Click here .gif)

7. DISCONNECT HV FLOOR UNDER WIRE

Click here .gif)

8. REMOVE REAR SEAT CUSHION ASSEMBLY

Click here .gif)

9. REMOVE REAR SEAT CUSHION LOCK HOOK

Click here .gif)

10. REMOVE REAR DOOR SCUFF PLATE LH

Click here .gif)

11. REMOVE REAR UNDER SIDE COVER LH

Click here .gif)

12. REMOVE REAR DOOR SCUFF PLATE RH

HINT:

Use the same procedure as for the LH side.

13. REMOVE REAR UNDER SIDE COVER RH

Click here .gif)

14. REMOVE REAR UNDER COVER

Click here .gif)

15. REMOVE REAR SEAT CUSHION LEG SUB-ASSEMBLY

Click here .gif)

16. REMOVE NO. 1 HV BATTERY COVER PANEL RH

Click here .gif)

17. DISCONNECT HV FLOOR UNDER WIRE

CAUTION:

Be sure to wear insulated gloves.

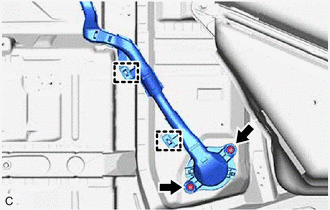

| (a) Disconnect the 2 HV battery junction block assembly connectors. NOTICE: Insulate each disconnected high-voltage connector with insulating tape. Wrap the connector from the wire harness side to the end of the connector. |

|

(b) Disconnect the shield ground from the HV battery.

| (c) Disconnect the floor wire connector. |

|

18. REMOVE FRONT EXHAUST PIPE ASSEMBLY

Click here .gif)

19. REMOVE EXHAUST MANIFOLD

Click here .gif)

20. REMOVE NO. 1 FLOOR UNDER COVER

Click here .gif)

21. REMOVE CENTER NO. 2 FLOOR HEAT INSULATOR

| (a) Remove the 3 nuts and center No. 2 floor heat insulator. |

|

22. DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

| (a) Remove the 2 nuts and disconnect the transmission control cable assembly. |

|

23. REMOVE HV FLOOR UNDER WIRE

CAUTION:

Be sure to wear insulated gloves.

NOTICE:

Insulate the disconnected connectors with insulating tape.

| (a) Remove the 2 nuts. |

|

(b) Remove the 2 clamps.

NOTICE:

If the clamps are removed forcibly, the stud bolts may be damaged.

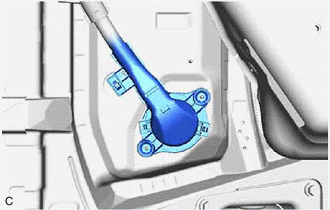

| (c) Disengage the grommet and pull out the HV floor under wire from the floor panel hole. |

|

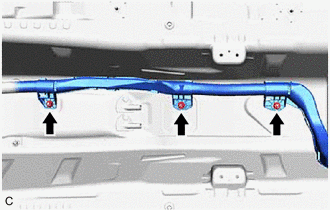

| (d) Remove the 3 nuts. |

|

| (e) Remove the 2 nuts and clamp. NOTICE: If the clamp is removed forcibly, the stud bolt may be damaged. |

|

| (f) Disengage the clamp. |

|

(g) Disconnect the HV floor under wire connector.

(h) Remove the nut and HV floor under wire.