Lexus ES: Low Pressure Fuel System Pressure - Too Low (P008A00)

DESCRIPTION

In order to supply the optimal fuel pressure according to the driving conditions and usage environment, the variable fuel system sends a drive signal from the ECM to the fuel pump control ECU, steplessly performing variable control of the fuel pump (for low pressure side) and receiving feedback about the fuel pressure (for low pressure side) from the No. 2 fuel pressure sensor (for low pressure side).

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Memory | Note |

|---|---|---|---|---|---|---|

| P008A00 | Low Pressure Fuel System Pressure - Too Low | The actual fuel pressure (for low pressure side) value is less than the target fuel pressure (for low pressure side) by a certain amount or more (1 trip detection logic). |

| Does not come on | DTC stored | SAE Code: P008A |

MONITOR DESCRIPTION

If the fuel pressure (for low pressure side) decreases despite an increase request signal being sent to the fuel pump control ECU by the ECM, the ECM will store this DTC.

MONITOR STRATEGY

| Frequency of Operation | Continuous |

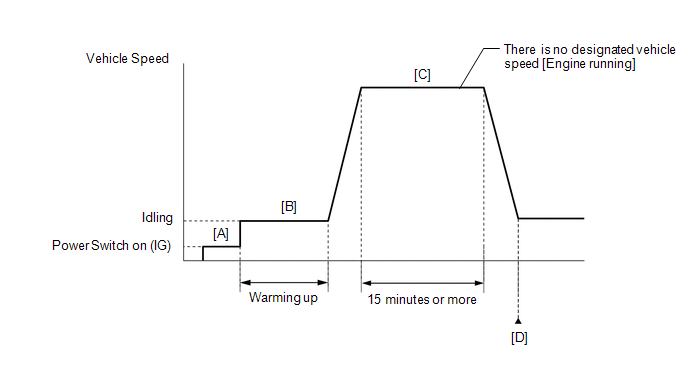

CONFIRMATION DRIVING PATTERN

- Connect the Techstream to the DLC3.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the power switch off and wait for at least 30 seconds.

- Turn the power switch on (IG) [A].

- Turn the Techstream on.

-

Put the engine in Inspection Mode (Maintenance Mode).

Click here

.gif)

- Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher [B].

-

With the engine running, drive the vehicle for 15 minutes or more [C].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

If the engine stops, further depress the accelerator pedal to restart the engine.

- Enter the following menus: Powertrain / Engine / Trouble Codes [D].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P008A00.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system has a malfunction.

- If the judgment result is INCOMPLETE, perform steps [B] through [D] again.

CAUTION / NOTICE / HINT

NOTICE:

-

Vehicle Control History may be stored in the hybrid vehicle control ECU assembly if the engine is malfunctioning. Certain vehicle condition information is recorded when Vehicle Control History is stored. Reading the vehicle conditions recorded in both the Freeze Frame Data and Vehicle Control History can be useful for troubleshooting.

Click here

.gif)

(Select Powertrain in Health Check and then check the time stamp data.)

Click here

.gif)

-

If any "Engine Malfunction" Vehicle Control History item has been stored in the hybrid vehicle control ECU assembly, make sure to clear it. However, as all Vehicle Control History items are cleared simultaneously, if any Vehicle Control History items other than "Engine Malfunction" are stored, make sure to perform any troubleshooting for them before clearing Vehicle Control History.

Click here

.gif)

HINT:

Read Freeze Frame Data using the Techstream. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

| 1. | CHECK FUEL LEAK |

(a) Check around and beneath the vehicle for fuel leaks, fumes, etc.

OK:

No fuel leaks present.

| NG | .gif) | REPAIR OR REPLACE FUEL LEAK POINT |

|

| 2. | CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P008A00) |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Trouble Codes.

(e) Read the DTCs.

Powertrain > Engine > Trouble Codes| Result | Proceed to |

|---|---|

| DTC P008A00 is output | A |

| DTC P008A00 and other DTCs are output | B |

HINT:

If any DTCs other than P008A00 are output, troubleshoot those DTCs first.

| B | .gif) | GO TO DTC CHART |

|

| 3. | PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE FUEL PUMP DUTY RATIO) |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump Duty Ratio.

Powertrain > Engine > Active Test| Tester Display |

|---|

| Control the Fuel Pump Duty Ratio |

(e) Check whether the fuel pump (for low pressure side) operating sound occurs when performing the Active Test on the Techstream.

Standard:

| Techstream Operation | Standard |

|---|---|

| High | Operating sounds can be heard from fuel pump (for low pressure side) |

HINT:

Perform "Inspection After Repair" after replacing the fuel pump (for low pressure side).

Click here .gif)

| NG | .gif) | REPLACE FUEL PUMP (FOR LOW PRESSURE SIDE) |

|

| 4. | PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE FUEL PUMP DUTY RATIO) |

(a) Discharge the fuel pressure.

HINT:

DTCs may be stored during this inspection. Check for DTCs and clear them using the Techstream.

(1) Remove the EFI-MAIN NO. 2 fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(2) Connect the Techstream to the DLC3.

(3) Turn the power switch on (IG).

(4) Turn the Techstream on.

(5) Put the engine in Inspection Mode (Maintenance Mode).

Powertrain > Hybrid Control > Utility| Tester Display |

|---|

| Inspection Mode |

(6) Start the engine.

(7) After the engine has stopped on its own, turn the power switch off.

HINT:

If the engine does not stop naturally, perform direct injection by racing the engine to reduce the fuel pressure [Fuel Pressure (High)] and stop the engine.

(8) Turn the power switch on (IG).

(9) Turn the Techstream on.

(10) Put the engine in Inspection Mode (Maintenance Mode).

Powertrain > Hybrid Control > Utility| Tester Display |

|---|

| Inspection Mode |

(11) Crank the engine again and make sure that the engine does not start.

(12) Install the EFI-MAIN NO. 2 fuse.

(b) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump Duty Ratio / Data List / Fuel Pressure (Low) / Fuel Pressure 2.

Powertrain > Engine > Active Test| Active Test Display |

|---|

| Control the Fuel Pump Duty Ratio |

| Data List Display |

|---|

| Fuel Pressure (Low) / Fuel Pressure 2 |

(c) Read the value displayed on the Techstream when the Active Test was performed.

Standard:

| Techstream Operation | Standard |

|---|---|

| Low to High | When switching from Low to High, Fuel Pressure (Low) / Fuel Pressure 2 value changes |

HINT:

Once the fuel pressure becomes high, the fuel pressure will not decrease, even when switched from High to Low. Therefore, make sure that the fuel pressure is low before checking that the fuel pressure changes when switching from Low to High.

| NG | .gif) | GO TO STEP 10 |

|

| 5. | PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE FUEL PUMP DUTY RATIO) |

(a) Discharge the fuel pressure.

HINT:

DTCs may be stored during this inspection. Check for DTCs and clear them using the Techstream.

(1) Remove the EFI-MAIN NO. 2 fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(2) Connect the Techstream to the DLC3.

(3) Turn the power switch on (IG).

(4) Turn the Techstream on.

(5) Put the engine in Inspection Mode (Maintenance Mode).

Powertrain > Hybrid Control > Utility| Tester Display |

|---|

| Inspection Mode |

(6) Start the engine.

(7) After the engine has stopped on its own, turn the power switch off.

HINT:

If the engine does not stop naturally, perform direct injection by racing the engine to reduce the fuel pressure [Fuel Pressure (High)] and stop the engine.

(8) Turn the power switch on (IG).

(9) Turn the Techstream on.

(10) Put the engine in Inspection Mode (Maintenance Mode).

Powertrain > Hybrid Control > Utility| Tester Display |

|---|

| Inspection Mode |

(11) Crank the engine again and make sure that the engine does not start.

(12) Install the EFI-MAIN NO. 2 fuse.

(b) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump Duty Ratio / Data List / Fuel Pressure (Low) / Fuel Pressure 2.

Powertrain > Engine > Active Test| Active Test Display |

|---|

| Control the Fuel Pump Duty Ratio |

| Data List Display |

|---|

| Fuel Pressure (Low) / Fuel Pressure 2 |

(c) Read the value displayed on the Techstream when the Active Test was performed.

Standard:

| Techstream Operation | Fuel Pressure (Low) / Fuel Pressure 2 |

|---|---|

| Low | 50 kPa or higher |

| High | 420 kPa or higher |

HINT:

Once the fuel pressure becomes high, the fuel pressure will not decrease, even when switched from High to Low. Therefore, make sure that the fuel pressure is low before checking that the fuel pressure changes when switching from Low to High.

OK:

Actual Low and High values are as shown above.

| NG | .gif) | GO TO STEP 9 |

|

| 6. | PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE FUEL PUMP DUTY RATIO) |

(a) Install the fuel pressure gauge (for low pressure side).

Click here .gif)

(b) Connect the Techstream to the DLC3.

(c) Turn the power switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump Duty Ratio / Data List / Fuel Pressure (Low) / Fuel Pressure 2.

Powertrain > Engine > Active Test| Active Test Display |

|---|

| Control the Fuel Pump Duty Ratio |

| Data List Display |

|---|

| Fuel Pressure (Low) / Fuel Pressure 2 |

(f) Compare the values in the Data List using the Techstream and the fuel pressure gauge when the Active Test was performed.

Standard:

| Techstream Operation | Standard |

|---|---|

| Low | Data List value and fuel pressure gauge are within +/-50 kPa of each other |

| High |

HINT:

Perform "Inspection After Repair" after replacing the No. 2 fuel pressure sensor (for low pressure side).

Click here .gif)

| NG | .gif) | REPLACE NO. 2 FUEL PRESSURE SENSOR (FOR LOW PRESSURE SIDE) |

|

| 7. | CLEAR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Clear the DTCs.

Powertrain > Engine > Clear DTCs(e) Turn the power switch off and wait for at least 30 seconds.

|

| 8. | CHECK WHETHER DTC OUTPUT RECURS (DTC P008A00) |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Enter the following menus: Powertrain / Engine / Utility / All Readiness.

Powertrain > Engine > Utility| Tester Display |

|---|

| All Readiness |

(c) Input the DTC: P008A00.

(d) Check the DTC judgment result.

| Result | Proceed to |

|---|---|

| NORMAL (DTCs are not output) | A |

| ABNORMAL (DTC P008A00 is output) | B |

| A | .gif) | CHECK FOR INTERMITTENT PROBLEMS |

| B | .gif) | REPLACE ECM |

| 9. | READ VALUE USING TECHSTREAM (FUEL PRESSURE (LOW) / FUEL PRESSURE 2) |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Put the engine in Inspection Mode (Maintenance Mode).

Powertrain > Hybrid Control > Utility| Tester Display |

|---|

| Inspection Mode |

(e) Start the engine.

(f) Enter the following menus: Powertrain / Engine / Data List / Fuel Pressure (Low) / Fuel Pressure 2.

Powertrain > Engine > Data List| Tester Display |

|---|

| Fuel Pressure (Low) / Fuel Pressure 2 |

(g) Record the Fuel Pressure (Low) / Fuel Pressure 2 value.

(h) Turn the power switch off.

(i) Wait for 10 seconds.

(j) Turn the power switch on (IG).

(k) Turn the Techstream on.

(l) Enter the following menus: Powertrain / Engine / Data List / Fuel Pressure (Low) / Fuel Pressure 2.

Powertrain > Engine > Data List| Tester Display |

|---|

| Fuel Pressure (Low) / Fuel Pressure 2 |

(m) Compare the Fuel Pressure (Low) / Fuel Pressure 2 value recorded with the engine running to the Fuel Pressure (Low) / Fuel Pressure 2 value currently shown on the Techstream.

| Result | Proceed to |

|---|---|

| Fuel Pressure (Low) / Fuel Pressure 2 value is maintained | A |

| Fuel Pressure (Low) / Fuel Pressure 2 value drops | B |

HINT:

Perform "Inspection After Repair" after replacing the fuel pump (for low pressure side).

Click here .gif)

| A | .gif) | REPLACE FUEL PUMP (FOR LOW PRESSURE SIDE) |

| B | .gif) | REPLACE FUEL MAIN VALVE ASSEMBLY (FOR HIGH PRESSURE) |

| 10. | PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE FUEL PUMP DUTY RATIO) |

(a) Install the fuel pressure gauge (for low pressure side).

Click here .gif)

(b) Connect the Techstream to the DLC3.

(c) Turn the power switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump Duty Ratio / Data List / Fuel Pressure (Low) / Fuel Pressure 2.

Powertrain > Engine > Active Test| Active Test Display |

|---|

| Control the Fuel Pump Duty Ratio |

| Data List Display |

|---|

| Fuel Pressure (Low) / Fuel Pressure 2 |

(f) Read the values in the Data List using the Techstream and the fuel pressure gauge when the Active Test was performed.

| Techstream Operation | Result | Proceed to |

|---|---|---|

| Low to High | Data List value does not change, but fuel pressure gauge changes | A |

| Data List value and fuel pressure gauge do not change | B |

HINT:

Perform "Inspection After Repair" after replacing the No. 2 fuel pressure sensor (for low pressure side).

Click here .gif)

| A | .gif) | REPLACE NO. 2 FUEL PRESSURE SENSOR (FOR LOW PRESSURE SIDE) |

| B | .gif) | REPLACE FUEL PUMP CONTROL ECU |

.gif)