Lexus ES: Installation

INSTALLATION

PROCEDURE

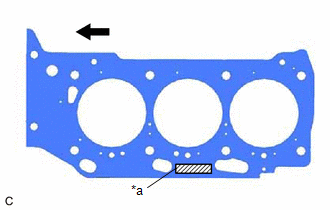

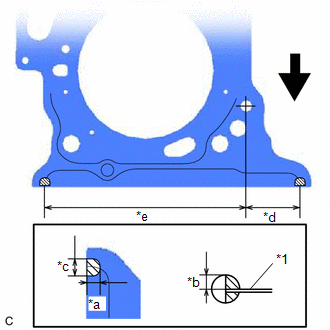

1. INSTALL NO. 2 CYLINDER HEAD GASKET

(a) Place a new No. 2 cylinder head gasket on the cylinder block sub-assembly as shown in the illustration.

| *a | Lot No. |

.png) | Front of Engine |

NOTICE:

- Remove any oil from the contact surfaces.

- Make sure to install the No. 2 cylinder head gasket in the correct direction.

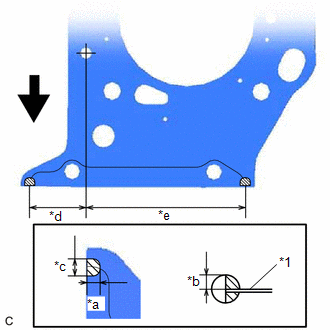

(b) Apply seal packing to the No. 2 cylinder head gasket as shown in the illustration.

Seal Packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

NOTICE:

- Remove any oil from the contact surfaces.

- Install the No. 2 cylinder head gasket within 3 minutes and tighten the cylinder head set bolts within 15 minutes of applying seal packing.

| *1 | No. 2 Cylinder Head Gasket |

| *a | 5.0 to 7.0 mm (0.197 to 0.276 in.) |

| *b | 3.0 to 5.0 mm (0.118 to 0.197 in.) |

| *c | 7.0 to 9.0 mm (0.276 to 0.354 in.) |

| *d | 38.2 mm (1.50 in.) |

| *e | 110.0 mm (4.33 in.) |

.png) | Front of Engine |

.png) | Seal Packing |

2. INSTALL CYLINDER HEAD LH

Click here .gif)

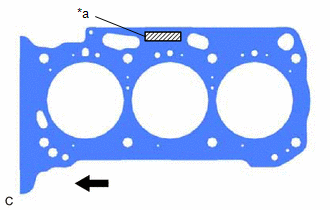

3. INSTALL CYLINDER HEAD GASKET

(a) Place a new cylinder head gasket on the cylinder block sub-assembly as shown in the illustration.

| *a | Lot No. |

.png) | Front of Engine |

NOTICE:

- Remove any oil from the contact surfaces.

- Make sure to install the cylinder head gasket in the correct direction.

(b) Apply seal packing to the cylinder head gasket as shown in the illustration.

Seal Packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

NOTICE:

- Remove any oil from the contact surfaces.

- Install the cylinder head gasket within 3 minutes and tighten the cylinder head set bolts within 15 minutes of applying seal packing.

| *1 | Cylinder Head Gasket |

| *a | 5.0 to 7.0 mm (0.197 to 0.276 in.) |

| *b | 3.0 to 5.0 mm (0.118 to 0.197 in.) |

| *c | 7.0 to 9.0 mm (0.276 to 0.354 in.) |

| *d | 38.5 mm (1.52 in.) |

| *e | 144.0 mm (5.67 in.) |

.png) | Front of Engine |

.png) | Seal Packing |

4. INSTALL CYLINDER HEAD SUB-ASSEMBLY

Click here .gif)

5. INSTALL WATER OUTLET

Click here .gif)

6. INSTALL VALVE STEM CAP

Click here .gif)

7. INSTALL VALVE LASH ADJUSTER ASSEMBLY

Click here .gif)

8. INSTALL NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

Click here .gif)

9. INSTALL NO. 1 CHAIN VIBRATION DAMPER

Click here .gif)

10. INSTALL NO. 2 CHAIN VIBRATION DAMPER

Click here .gif)

11. INSTALL SENSOR WIRE

Click here .gif)

12. INSTALL NO. 3 CAMSHAFT SUB-ASSEMBLY

Click here .gif)

13. INSTALL NO. 4 CAMSHAFT SUB-ASSEMBLY

Click here .gif)

14. INSTALL CAMSHAFT BEARING CAP (for Bank 2)

Click here .gif)

15. SET CAMSHAFT TIMING GEAR ASSEMBLY, CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY AND NO. 2 CHAIN SUB-ASSEMBLY (for Bank 2)

Click here .gif)

16. TEMPORARILY INSTALL CAMSHAFT TIMING GEAR BOLT (for Intake Side of Bank 2)

Click here .gif)

17. TEMPORARILY INSTALL CAMSHAFT TIMING GEAR BOLT (for Exhaust Side of Bank 2)

Click here .gif)

18. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY LH

Click here .gif)

19. TIGHTEN CAMSHAFT TIMING GEAR BOLT (for Intake Side of Bank 2)

Click here .gif)

20. TIGHTEN CAMSHAFT TIMING GEAR BOLT (for Exhaust Side of Bank 2)

Click here .gif)

21. INSTALL CAMSHAFT

Click here .gif)

22. INSTALL NO. 2 CAMSHAFT

Click here .gif)

23. INSTALL CAMSHAFT BEARING CAP (for Bank 1)

Click here .gif)

24. SET CAMSHAFT TIMING GEAR ASSEMBLY, CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY AND NO. 2 CHAIN SUB-ASSEMBLY (for Bank 1)

Click here .gif)

25. TEMPORARILY INSTALL CAMSHAFT TIMING GEAR BOLT (for Intake Side of Bank 1)

Click here .gif)

26. TEMPORARILY INSTALL CAMSHAFT TIMING GEAR BOLT (for Exhaust Side of Bank 1)

Click here .gif)

27. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY

Click here .gif)

28. TIGHTEN CAMSHAFT TIMING GEAR BOLT (for Intake Side of Bank 1)

Click here .gif)

29. TIGHTEN CAMSHAFT TIMING GEAR BOLT (for Exhaust Side of Bank 1)

Click here .gif)

30. INSTALL NO. 3 CHAIN TENSIONER ASSEMBLY

Click here .gif)

31. INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY

Click here .gif)

32. INSTALL CHAIN SUB-ASSEMBLY

Click here .gif)

33. INSTALL CHAIN TENSIONER SLIPPER

Click here .gif)

34. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

Click here .gif)

35. INSPECT VALVE TIMING

Click here .gif)

36. INSTALL TIMING CHAIN COVER ASSEMBLY

Click here .gif)

37. INSTALL TIMING CHAIN CASE OIL SEAL

Click here .gif)

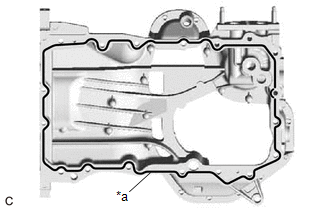

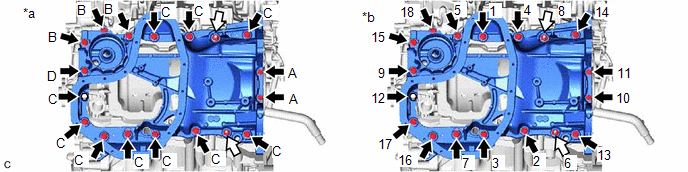

38. INSTALL OIL PAN SUB-ASSEMBLY

(a) Install 2 new oil pan gaskets to the timing chain cover assembly.

| (b) Apply seal packing in a continuous line as shown in the illustration. Seal Packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Seal Packing Diameter: 3.0 to 4.0 mm (0.118 to 0.157 in.) NOTICE:

|

|

(c) Install the oil pan sub-assembly with the 16 bolts and 2 nuts in the order shown in the illustration.

| *a | Torque | *b | Bolt and Nut Tightening Order |

.png) | Bolt | .png) | Nut |

Torque:

Bolt (A) :

10 N·m {102 kgf·cm, 7 ft·lbf}

Bolt (B), (C), (D) :

21 N·m {214 kgf·cm, 15 ft·lbf}

Nut :

21 N·m {214 kgf·cm, 15 ft·lbf}

Bolt Length:

| Item | Length |

|---|---|

| Bolt (A) | 16 mm (0.630 in.) |

| Bolt (B) | 45 mm (1.77 in.) |

| Bolt (C) | 25 mm (0.984 in.) |

| Bolt (D) | 70 mm (2.76 in.) |

(d) Wipe off any excess seal packing with a clean piece of cloth.

NOTICE:

Do not allow seal packing to contact the No. 1 crankshaft position sensor plate.

.png) | Wipe off the Seal Packing |

39. INSTALL OIL STRAINER SUB-ASSEMBLY

Click here .gif)

40. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY

Click here .gif)

41. INSTALL SPARK PLUG TUBE GASKET

Click here .gif)

42. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY LH

Click here .gif)

43. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

Click here .gif)

44. INSTALL SENSOR WIRE

Click here .gif)

45. INSTALL CRANKSHAFT POSITION SENSOR PROTECTOR

Click here .gif)

46. INSTALL CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 2)

Click here .gif)

47. INSTALL CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Exhaust Side of Bank 2)

Click here .gif)

48. INSTALL CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Exhaust Side of Bank 1)

Click here .gif)

49. INSTALL CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 1)

Click here .gif)

50. INSTALL WATER INLET WITH THERMOSTAT SUB-ASSEMBLY

Click here .gif)

51. CONNECT WATER BY-PASS HOSE

Click here .gif)

52. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET LH

Click here .gif)

53. INSTALL CRANKSHAFT PULLEY

Click here .gif)

54. INSTALL WATER FILLER BRACKET

Click here .gif)

55. INSTALL WIRE HARNESS CLAMP BRACKET

Click here .gif)

56. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE

Click here .gif)

57. INSTALL WATER PUMP PULLEY

Click here .gif)

58. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

Click here .gif)

59. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

Click here .gif)

60. INSTALL COMPRESSOR ASSEMBLY WITH MAGNETIC CLUTCH

Click here .gif)

61. INSTALL GENERATOR ASSEMBLY

Click here .gif)

62. INSTALL V-RIBBED BELT

Click here .gif)

63. INSTALL VACUUM PUMP ASSEMBLY

-

for TMMK Made:

Click here

.gif)

-

for TMC Made:

Click here

.gif)

64. INSTALL IGNITION COIL ASSEMBLY

Click here .gif)

65. INSTALL KNOCK CONTROL SENSOR

Click here .gif)

66. INSTALL ENGINE HANGERS

Click here .gif)

.gif)

67. REMOVE ENGINE ASSEMBLY FROM ENGINE STAND

Click here .gif)