Lexus ES: Voice Recognition Microphone Disconnected (B1579)

DESCRIPTION

The radio receiver assembly and telephone microphone assembly are connected to each other using the microphone connection detection signal lines.

This DTC is stored when a microphone connection detection signal line is disconnected.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| B1579 | Voice Recognition Microphone Disconnected | Microphone signal is lost. |

|

- *: w/ Manual (SOS) Switch

WIRING DIAGRAM

w/ Manual (SOS) Switch w/o Manual (SOS) Switch

w/o Manual (SOS) Switch .png)

CAUTION / NOTICE / HINT

NOTICE:

-

Depending on the parts that are replaced during vehicle inspection or maintenance, performing initialization, registration or calibration may be needed. Refer to Precaution for Audio and Visual System.

Click here

.gif)

-

When replacing the radio receiver assembly, always replace it with a new one. If a radio receiver assembly which was installed to another vehicle is used, the following may occur:

- A communication malfunction DTC may be stored.

- The radio receiver assembly may not operate normally.

-

Before replacing the DCM (telematics transceiver), refer to Registration.

Click here

.gif)

PROCEDURE

| 1. | INSPECT RADIO RECEIVER ASSEMBLY |

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) | REPLACE RADIO RECEIVER ASSEMBLY |

|

| 2. | CHECK MODEL |

(a) Choose the model to be inspected.

| Result | Proceed to |

|---|---|

| w/ Manual (SOS) Switch | A |

| w/o Manual (SOS) Switch | B |

| B | .gif) | GO TO STEP 8 |

|

| 3. | CHECK HARNESS AND CONNECTOR (DCM (TELEMATICS TRANSCEIVER) - TELEPHONE MICROPHONE ASSEMBLY) |

(a) Disconnect the G128 DCM (telematics transceiver) connector.

(b) Disconnect the P18 telephone microphone assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| G128-7 (MCI-) - P18-4 (MCO-) | Always | Below 1 Ω |

| G128-7 (MCI-) or P18-4 (MCO-) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. | CHECK HARNESS AND CONNECTOR (RADIO RECEIVER ASSEMBLY - DCM (TELEMATICS TRANSCEIVER)) |

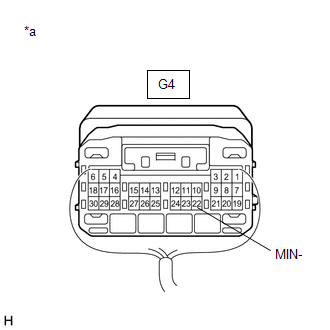

(a) Disconnect the G4 radio receiver assembly connector.

(b) Disconnect the G128 DCM (telematics transceiver) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| G4-22 (MIN-) - G128-32 (MCO-) | Always | Below 1 Ω |

| G4-22 (MIN-) or G128-32 (MCO-) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. | CHECK HARNESS AND CONNECTOR (RADIO RECEIVER ASSEMBLY - TELEPHONE MICROPHONE ASSEMBLY) |

(a) Disconnect the G4 radio receiver assembly connector.

(b) Disconnect the P18 telephone microphone assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| G4-25 (SNS2) - P18-3 (SNS2) | Always | Below 1 Ω |

| G4-25 (SNS2) or P18-3 (SNS2) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 6. | INSPECT DCM (TELEMATICS TRANSCEIVER) |

(a) Reconnect the G128 DCM (telematics transceiver) connector.

(b) Reconnect the G4 radio receiver assembly connector.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(d) Proceed to the next step based on the inspection result.

| NG | .gif) | REPLACE DCM (TELEMATICS TRANSCEIVER) |

|

| 7. | INSPECT TELEPHONE MICROPHONE ASSEMBLY |

(a) Remove the telephone microphone assembly.

Click here .gif)

| (b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) | REPLACE RADIO RECEIVER ASSEMBLY |

| NG | .gif) | REPLACE TELEPHONE MICROPHONE ASSEMBLY |

| 8. | CHECK HARNESS AND CONNECTOR (RADIO RECEIVER ASSEMBLY - TELEPHONE MICROPHONE ASSEMBLY) |

(a) Disconnect the G4 radio receiver assembly connector.

(b) Disconnect the P18 telephone microphone assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| G4-25 (SNS2) - P18-3 (SNS2) | Always | Below 1 Ω |

| G4-22 (MIN-) - P18-4 (MCO-) | Always | Below 1 Ω |

| G4-25 (SNS2) or P18-3 (SNS2) - Body ground | Always | 10 kΩ or higher |

| G4-22 (MIN-) or P18-4 (MCO-) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 9. | INSPECT TELEPHONE MICROPHONE ASSEMBLY |

(a) Remove the telephone microphone assembly.

Click here .gif)

| (b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) | REPLACE RADIO RECEIVER ASSEMBLY |

| NG | .gif) | REPLACE TELEPHONE MICROPHONE ASSEMBLY |

.gif)